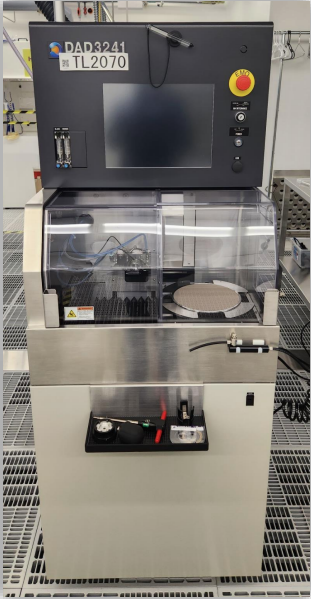

- The Disco DAD3241 is a high-productivity automatic dicing saw that supports large workpieces up to Φ8”. Equipped with servo motors on all axes and a high-output 1.8kW spindle, it can handle difficult-to-cut materials from silicon to ceramics.

➢ DAD3241 features high index accuracy, a built-in microscope, communication control through PC and touch screen via a specialized interface system.

➢ DAD3241 works with Model 3150 Tape Applicator for easy bubble-free sample mounting

➢ Blades for silicon, glass, and sapphire samples are provided:

• Disco Z09 Blades: 35 micron thickness, for silicon only

• Disco R07 Blades: 200 micron thickness, for glass and silicon

• Disco KR15 Blades: 200 micron thickness and low grit, for sapphire, glass, and silicon

➢ Specifications

• Max. workpiece size: Φ8”

• X-/Y-axis cutting range: 210 mm

• Cutting speed: 0.1-800 mm/s

• Index positioning accuracy: 0.002/210 mm

• Z-axis max. stroke: 32.2 mm

• Moving resolution: 0.000002 mm

• Repeatability accuracy 0.001 mm

• Θ-axis max. rotating angle: 320°

• Rotation speed range: 6,000-60,000 rpm

Please use the iLab system to schedule time to use this equipment.

***Note that a special tape and UV curing system are available to ease removal of diced die from tape***

Flyer for dicing saw and tape applicator

Standard Operating Procedure for Disco Dicing Saw and Tape Applicator