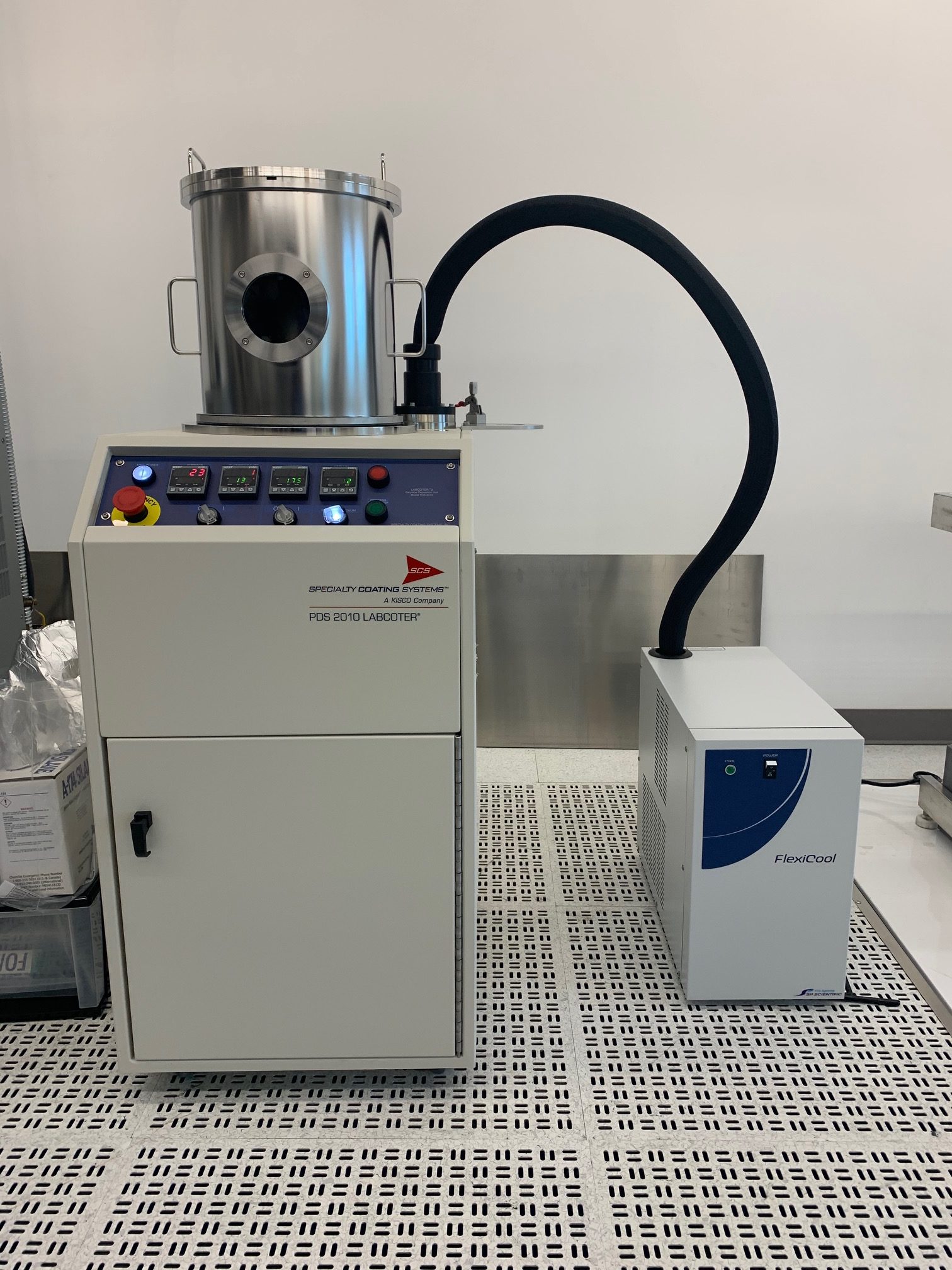

The PDS 2010 is a vacuum system used for the vapor deposition of Parylene polymer onto a variety of substrates. The clear polymer coating provides an extremely effective chemical and moisture barrier and has a high dielectric constant and mechanical strength.

The Parylene process sublimates a dimer into a gaseous monomer. The monomer then polymerizes at room temperature onto the

substrate. At the vacuum levels used, all sides of the substrate are uniformly impinged by the gaseous monomer, resulting in a conformal coating.

Key Features:

– Wafer size: From small pieces up to 8”

– Can load non-flat samples

– Rotating Platter/sample holder

– Rough Vacuum

– Mechanical Chiller

– Semi-Automatic Run Mode

There are 3 different types of monomers, and Parylene C is provided by AggieFab:

Parylene N is the basic member of the series. Parylene N is poly-P-xylylene, a completely linear, highly crystalline material. Parylene N molecules are extremely elastic and will “bounce” around many times before depositing and polymerizing. This results in greater penetration, into small openings, than other types of Parylene. The expected increase of pressure in the deposition chamber during a coating run is controlled at a higher pressure than the other Parylene types. Parylene N deposits at a rate of approximately .00003″ per hour, a much slower rate than Parylene C or D.

Parylene C is commercially available and is produced from the same monomer modified only by the substitution of a chlorine atom for one of the aromatic hydrogen atoms. Parylene C molecules are less elastic than N molecules and “bounce” around considerably less than N. The pressure in the Deposition Chamber is controlled at a value of approximately one half that for Parylene N. Deposition rates for Parylene C are in the order of .0002″ per hour.

Parylene D is commercially available and is produced from the same monomer modified by the substitution of two chlorine atoms for two of the aromatic hydrogen atoms. Parylene D molecules are not very elastic. They will deposit and polymerize very quickly upon entering the deposition chamber. The associated pressure rise during deposition is quite low. If the use of Parylene D is required for your application, contact SCS Engineering for special process considerations involved with its use in the 2010.

Please use iLab to reserve time on this tool.