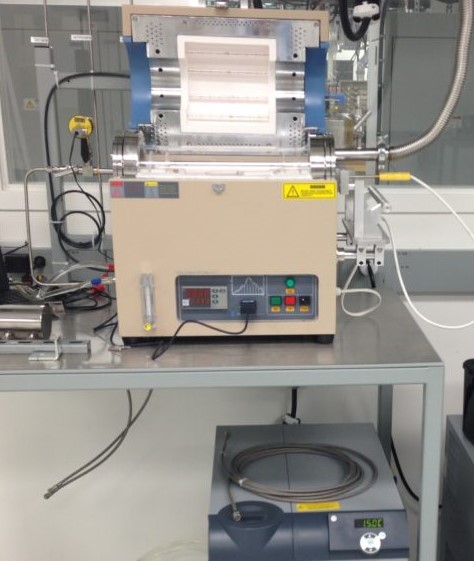

MTI D4

The MTI RTP is a compact rapid thermal processing tube furnace that is designed for annealing wafers coated with metallic films and metal samples up to 1000°C.

Tube: 4” O.D. quartz tube

Maximum Temperature: 1000°C (for <10/min)

Working Temperature: 400°C (continuous), 600°C (< 1 hour)

Suggested Normal Heating Rate: 10-25°C /sec

Maximum Heating Rate: 50°C /sec

Constant Temperature zone: 4″ (+/-1°C) @ 1000°C

Please use the iLab system to schedule time to use this equipment.